A Living Production

The Principle of Human Quality Control

The dreams are born from the roll, achieving powerful dimensions.

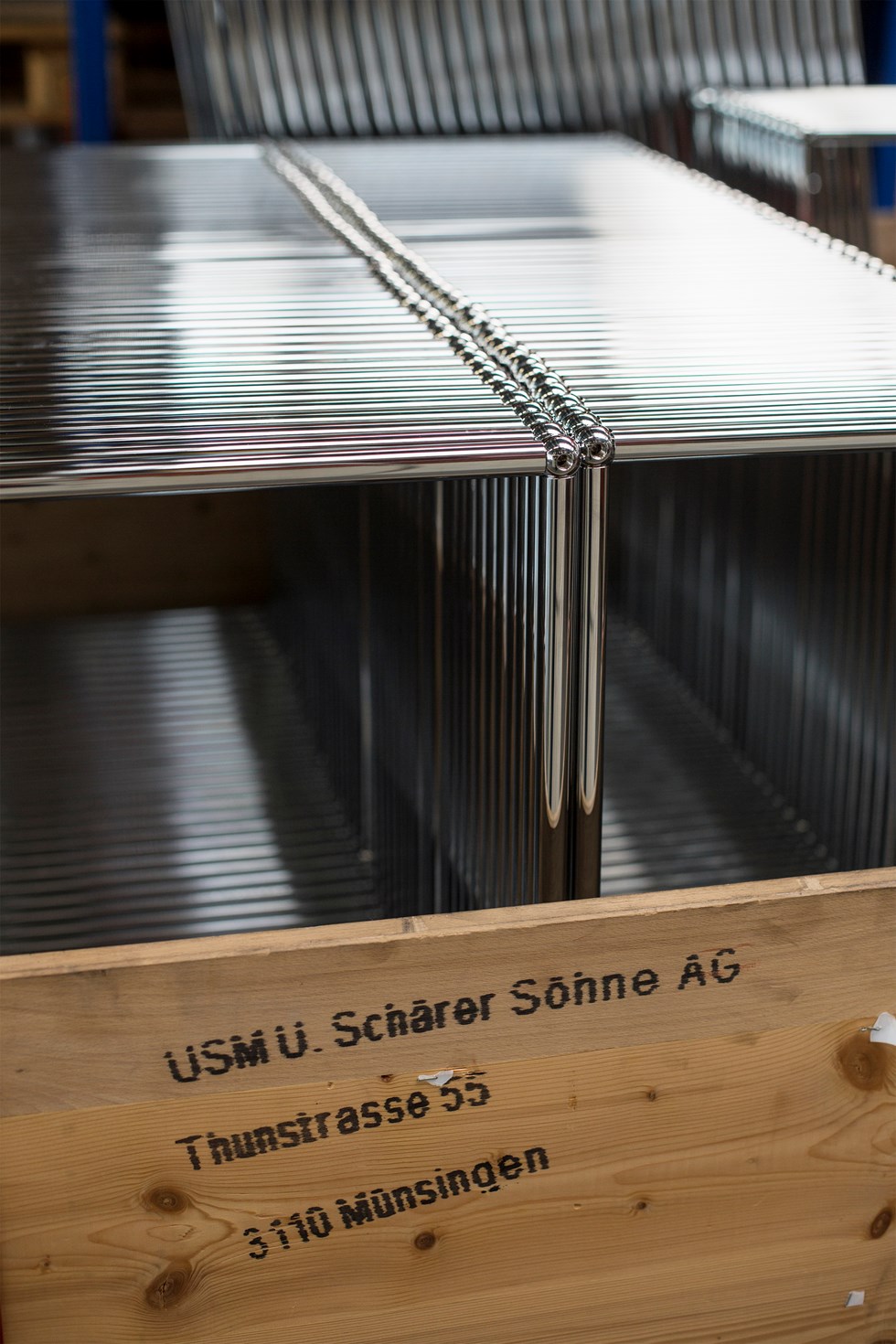

No one at the USM headquarters in Münsingen, Switzerland, wonders about the delivery of two kilometers of steel plating. The imposing rolls are everyday business here. Thousands and thousands of parts for the modular furniture systems will soon be cut from them, in the precise amount and measure which the customer wants and needs. Manufacturing in advance is virtually unknown here in Münsingen. The character of a product also has a significant impact on production. At USM, this primarily means individuality in addition to quality.

One roof. Four beams. Façades. “Our furniture is like buildings,” says Alexander Schärer, CEO and owner of USM. He is standing in the steel-and- glass pavilion in which Switzerland’s first open-plan office was created long ago, and whose building structure serves as a model for USM Modular Furniture Haller. From large to small, and from small to large. The factory is reminiscent of the furniture – and vice versa. Of course, in light of the unique company history, this is not possible any other way. Münsingen is and remains the exclusive manufacturing location of USM.

After expanding the manufacturing facilities three different times, the “Pavillon” is now the architectural jewel in the heart of USM headquarters. The company continues to grow; its biggest change was introduced in spring 2013 with a new powder coating plant. USM invested over ten million Swiss francs for a complex featuring the latest technology, spanning an area the size of 14 tennis courts. Alexander Schärer points in the direction of the facility, and there is a very good reason why he's smiling: because you cannot see anything from the pavilion. The custom-designed USM

facility is located underground, making it possible to build the impressive technical structure of chambers, assembly lines and ovens without disrupting ongoing operations.

In the space, which could easily host a Wimbledon tournament, powder is being sprayed onto four fully automatic paint conveyors. This is how 5,600 square meters of metal parts are coated in the legendary 14 colors for USM Modular Furniture Haller every day: a tremendous increase in capacity.

The powder coating facility as a centerpiece is also a clear commitment to

manufacturing in Switzerland and the globally recognized value factor of “Swissness”. Here, high quality standards, optimal production conditions and flexible processes can be guaranteed. The impressive machinery, in which charged powder particles are evenly sprayed on a grounded workpiece, increases capacity, decreases risk, increases flexibility and improves working conditions. Overall, the measures also demonstrate what active sustainability means at USM. Energy consumption alone is reduced by up to 30%.

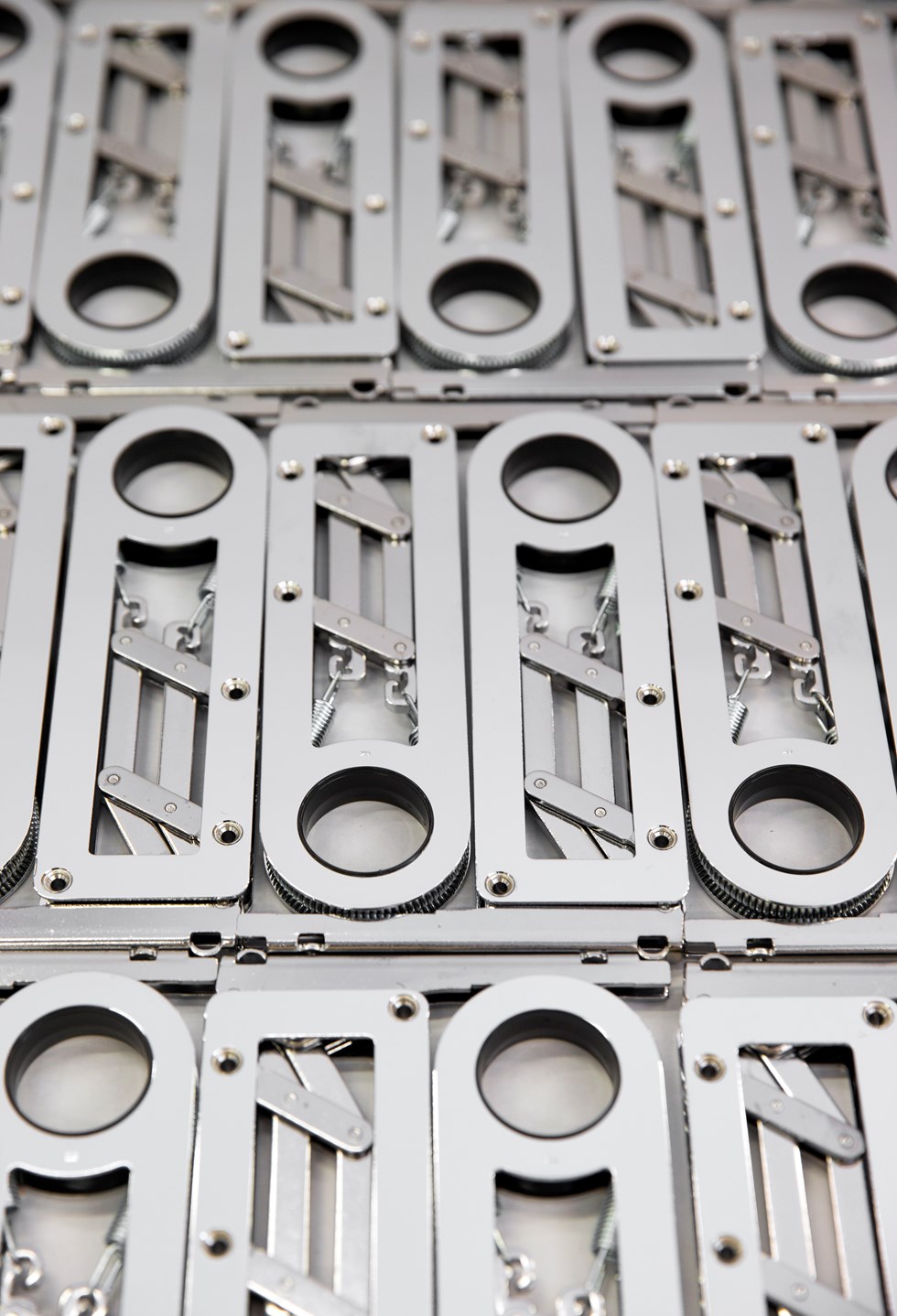

Above all, the capacity of the product to maintain its value is the largest contributing factor to sustainability. Decisions regarding this longevity are also made early in the production process. Intelligent tools and proper control systems implement the company's tradition with forward-thinking resources. The human factor will always remain essential wherever machines provide employees with considerable support for handcrafted work. USM customers worldwide have the same understanding of

and the same demands for quality. That's why precision and reliability aren't just left up to machinery but constitute a vital need for the employee's human touch. This is also reflected when the individual parts, which are accompanied by a digital control slip with the exact customer request for configuration throughout the entire production process, reach the assembly hall. The elements are either fully assembled here or pre-assembled into small transportable units to be shipped worldwide. “The human eye is still our best quality control,” says Alexander Schärer, “manually inspecting each piece multiple times.” Parts manufactured by machines are individually assembled. Nothing can hide from the trained eye. Of course, it certainly helps that the most USM employees have worked for the company for an average of 15 years. A company's intrinsic values also define it.

This is how the production process creates expertise. And furniture, too, of course – from one person to another.